Built off-site, these permanent-grade, transitional facilities provide the right building, at the right time, for as long as it’s needed. This helps NHS providers ensure their estate strategies keep pace with the Government’s ambitions for health system reform.

From discharge lounges and same day emergency care (SDEC) to surgical hubs and ward accommodation, we deliver transformational permanent-grade facilities for a wide range of clinical and non-clinical applications. This helps to alleviate capacity pressures, support service resilience, and reduce elective care waiting lists, while building future flexibility into the healthcare estate.

Through our parent company, which has operated in the UK for over 60 years, Darwin Group benefits from access to the largest modular manufacturing capacity and fleet in the country. Built in factory-controlled conditions and compliant with HBN and HTM standards, our On-Demand® facilities are rapidly deployable and scalable to each project’s requirements, ensuring they meet the highest standards of clinical excellence.

Flexible design solutions

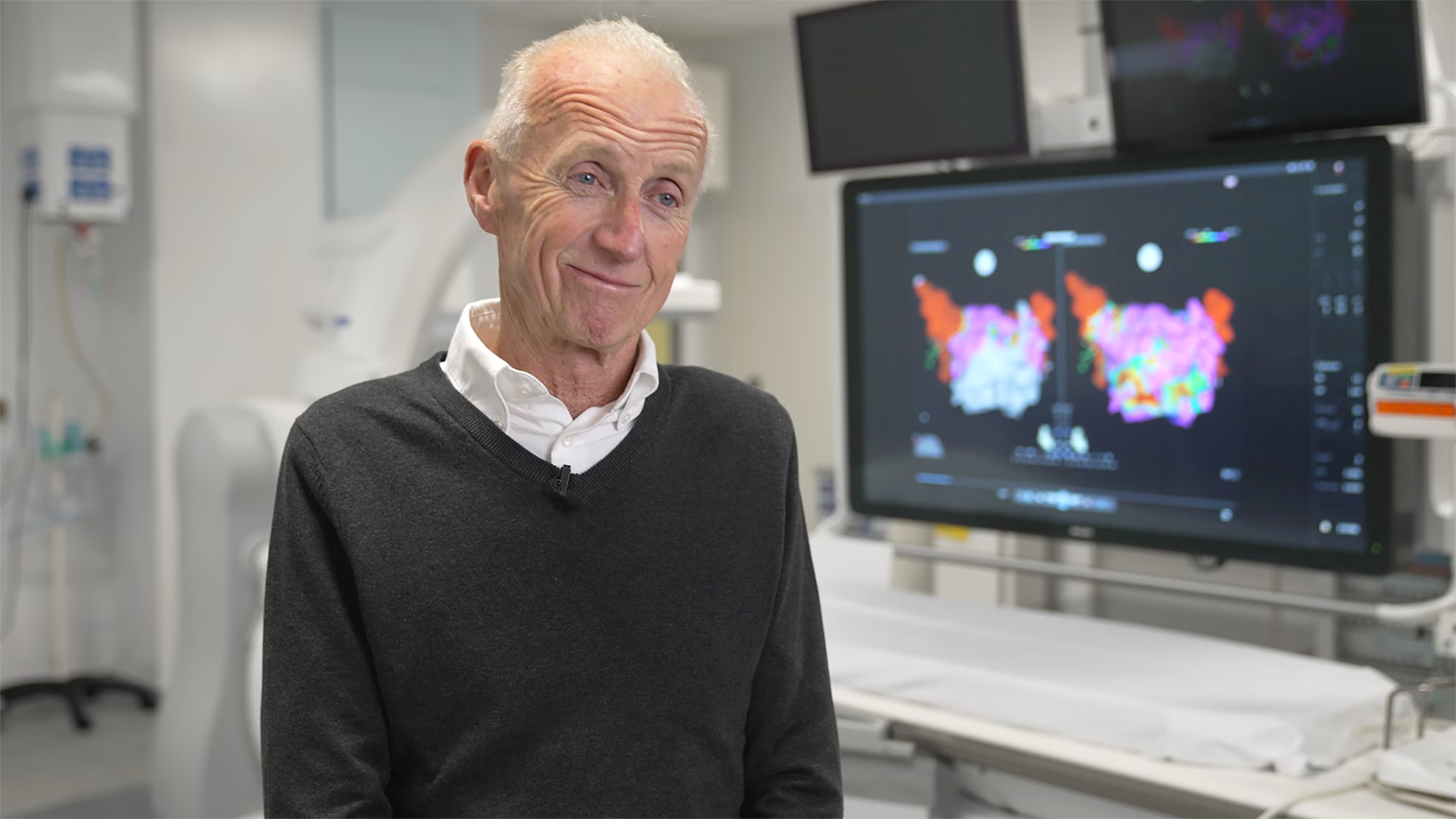

Our team of healthcare experts has developed an in-depth understanding of how to create flexible design solutions that meet complex clinical care requirements.

Acting as architect and lead design consultants, we optimise smart technology with patient care central to every decision. Our adaptable On-Demand buildings can also be reconfigured as the need arises, meeting the ever-changing requirements of modern healthcare.

The buildings we design are not just fit for purpose, they also surpass rigorous best practice guidelines. Digitally designed and virtually tested to ensure accuracy at every stage, Design for Manufacture and Assembly (DfMA) principles are integrated throughout the design and development path. This results in better quality outcomes, and design that achieves higher sustainability standards.

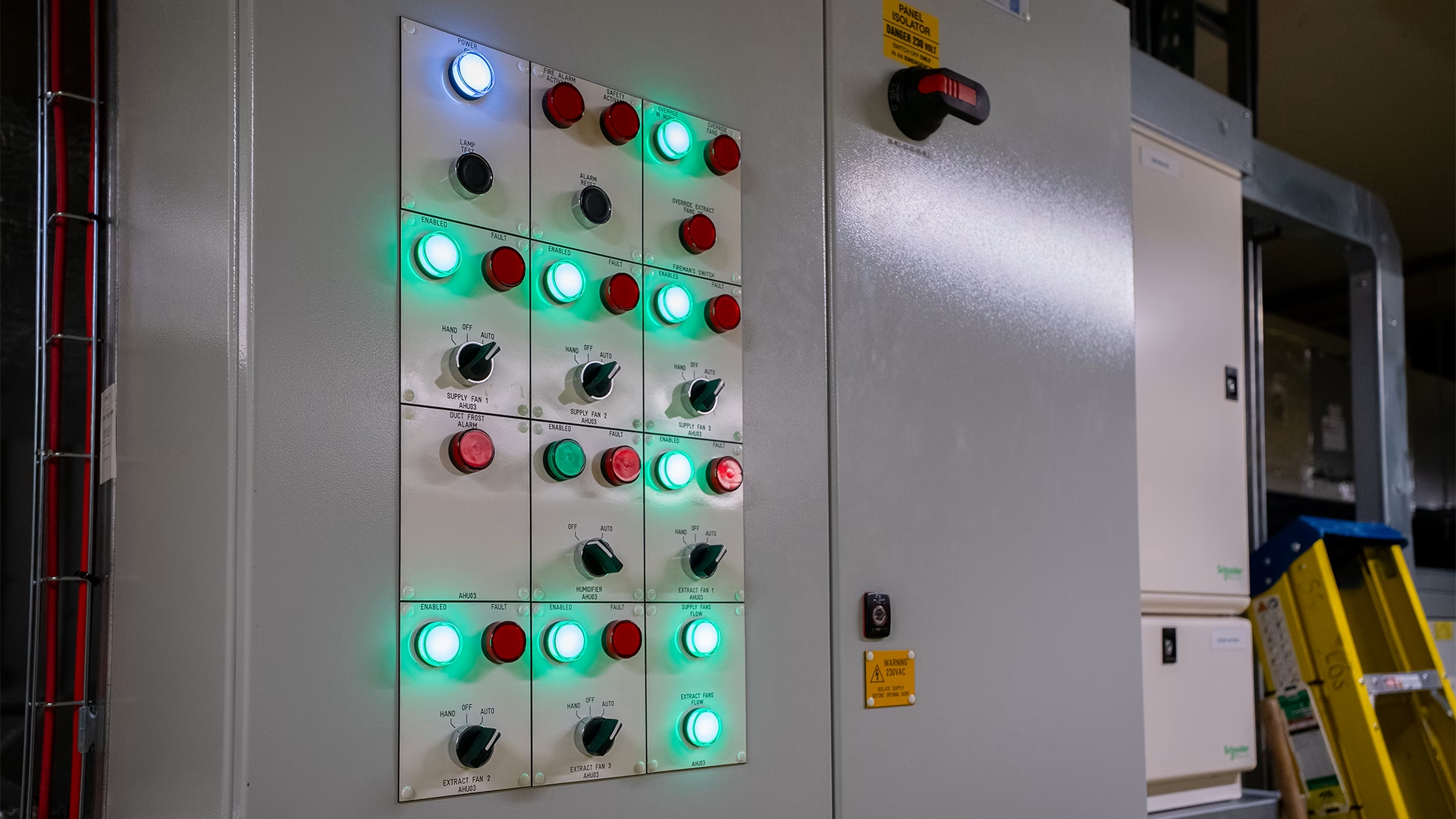

We operate our own manufacturing facility, providing superb quality control over every aspect of production, as well as the specification of materials. Our innovative approach to modern methods of construction delivers non-combustible, modular steel super-structures with a minimum design life of more than 60 years.

This manufacturing process has been developed over many years, specifically to meet the needs of clinicians and healthcare estates. By moving the construction process into our regulated factory environment, we can validate the performance of materials and enhance the quality of the build. Combined with rigorous inspection procedures, Darwin Group’s total quality management approach creates a climate for continual improvement and helps us achieve our objective of zero defects.

Our team have developed build techniques to precisely meet NHS requirements for adaptable buildings and inspection regimes. Through our pioneering approach to construction, the quality and precision realised in the production of the super-structure continues across the onsite environment. Combining DfMA principles with innovative on-site techniques, designs are conceived for seamless assembly. The installation of our prefabricated building modules is carried out by our highly skilled onsite teams, supported by the latest technology including exoskeletons, robotics, drone verification tools and advanced site machinery.

Modules are transported to site to create a watertight structure in a matter of days. Exceeding building regulations, our aim is always to offer the highest quality of onsite installation and finish, based on national best practice guidelines.

As healthcare experts, we have an in-depth understanding of complex clinical care requirements, NHS commissioning protocols and the challenges involved. In close collaboration with NHS experts and independent commissioning specialists, our testing regimes are comprehensive from concept to completion. Verification throughout design, manufacture and final installation ensures excellent, repeatable quality and optimises outcomes to enhance patient care and clinical satisfaction.